Facing and Squaring

Tube Squaring 300 Series

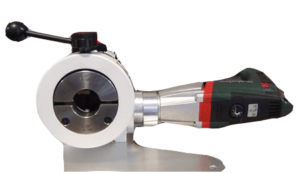

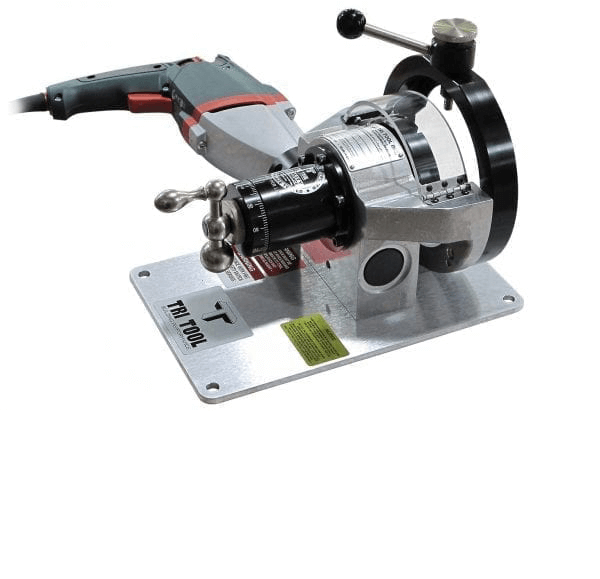

300 MF Tube Cutting and Squaring

This quick squaring tool creates the perfect prep for autogenous tube welding. The Model 300 MICROFACER tube squaring machine accepts its own torque through the self-contained OD saddle clamping system for precision squared ends. This standard saddle clamping system requires a straight length of tube .40″ (10.2mm) long. The tube squaring machine’s speed control is provided by a variable speed cordless electric drive. Feed is controlled by a cam actuated feed handle, located at a right angle to the cutter head.

301SP Tube Squaring Machine

301.5 SP Tube Squarer

Model 302 Tube Squaring Machine

Model 304 Tube Squarer

Tri Tool offers several other 300 Series tube squaring machines to meet your application requirements:

- Model 301

- Model 301 SP

- Model 301.5 SP

- Model 302

- Model 304

- Model 306

- Model 308

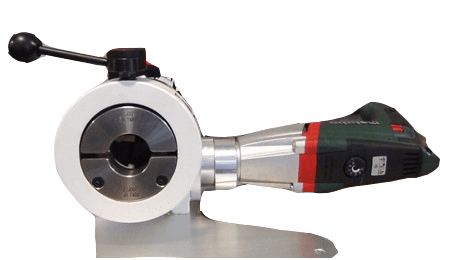

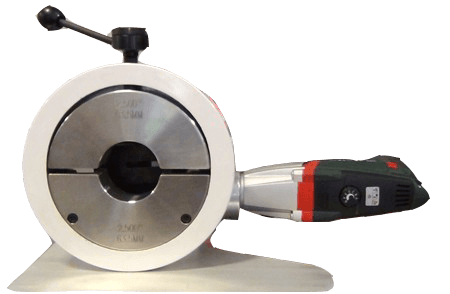

Tube SquareDevil

LEFON SquareDevil

LEFON SquareDevil, the portable tube squaring machine is specially designed to flatten and bevel tube end, making it burr-free, and perfect straight to the axis of the tube. After facing, the tube would be ready for orbital welding or other tube fabrication, ideal for high purity / high sanitary industry use, such as Beverage, Dairy, Pharmaceutics, Water treatment, Food, Semi-conductor industry etc.

Key Features:

- Faces and Bevels most metals including stainless steel,nickel and carbon steels, chrome, copper-nickel alloy, aluminum

- Wide range of collets (clamp)/ OD Mounting Saddles available, to avoid any tube distortion

- Three SquareDevil model available, to work on tube from 1/8″ OD to 4 1/2″ OD

- High quality collets made from stainless steel rather than aluminum

- Can face and bevel tube wall thickness up to 10mm

- 120/220 V powerful Metabo electrical motor

- Micro feed system

- Supply full range of bevel and squaring bits

Tube Severing 500 Series

Capabilities of our 500 Series tube cutting machines include:

- Rapid set-up and cycle times boosts productivity

- Auto-cycling feature automatically resets the tool bit after each cut

- The Quick-Lock lever quickly locks the stainless steel collet in place

- Tool bit severing produces a superior weld-ready, burr-free finish

- The self-centering stainless steel full contact OD collet eliminates damage to thin wall tubes

- Minimizes risk of contamination

- Tool bit cold cutting produces easily collectible ribbon-like chips – no saw blades that produce particulate

The Model 572AC SEVERMASTER™

576 AC Tube Severing Machine

5712AC Tube Severing Machine

High production with consistent repeatable performance over and over again, our model 5712AC delivers a weld-ready finish on large tube and thin wall pipe. The perfect weld prep for your tube welding needs.

- The variable speed motor increases tool bit life and reduces burrs

- Smooth roller bearing design for perfect severs

- Four interchangeable, self-centering collets prevent distortion of thin wall tubing

- The unique hybrid saddle and collet system, accept torque while providing reliable, secure clamping

TriTool 500 Series Models Available

- -550 CTC

- -572 AC

- -576 AC

- -5712 AC

- -5716 AC